Our services

Autocirc Rematrontech performs remanufacturing of vehicle components within two main business areas:

Emission systems

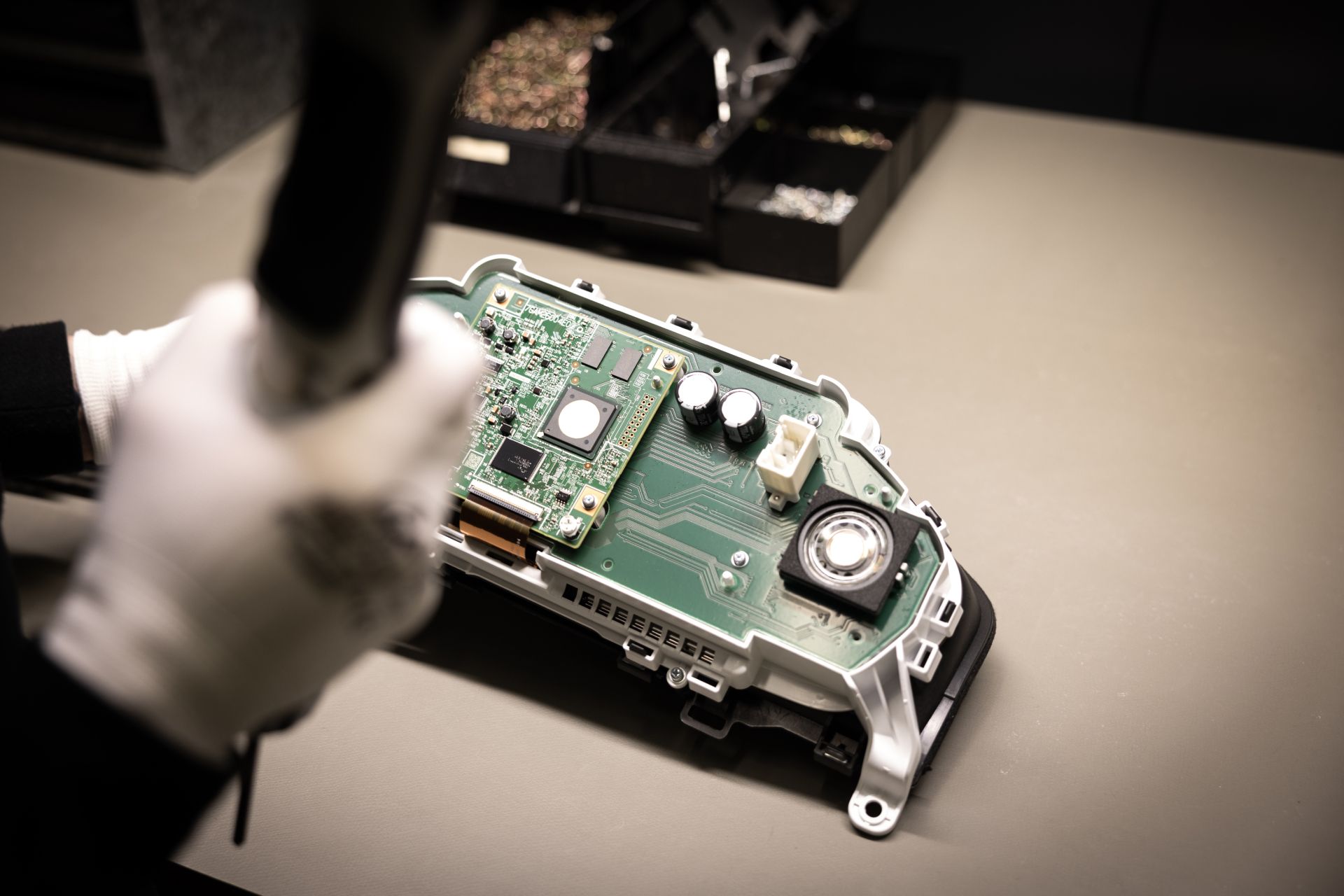

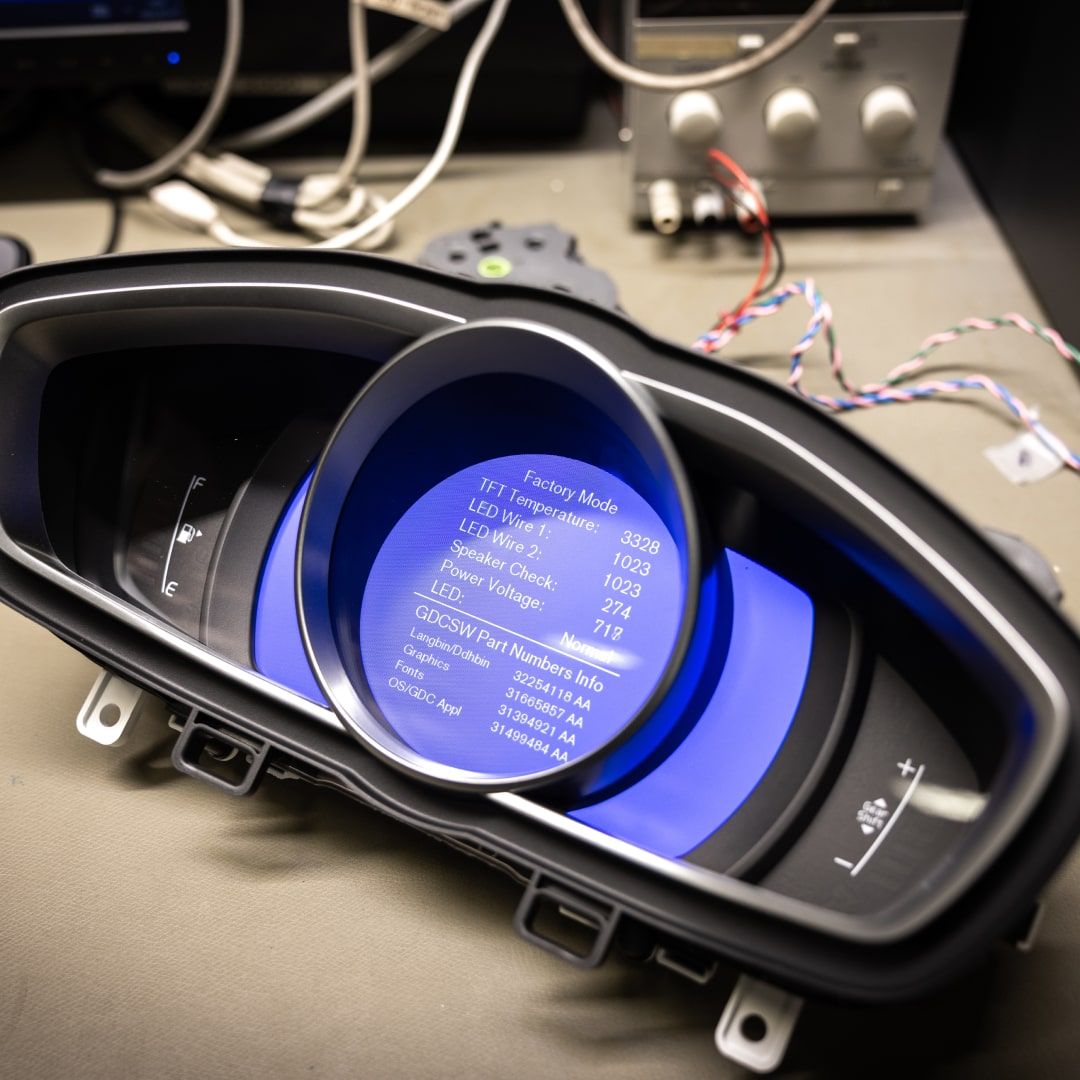

Electronics

EMISSION SYSTEMS

Diesel particulate Filter

We are at the forefront of Diesel Particulate Filter (DPF) cleaning.

The limited life of today’s Diesel Particulate Filters represents a growing concern for the automotive industry. Basically, the filters clog up prematurely. The main culprits – city traffic, driving short distances and software glitches–prevent filters from running at the right temperature. Replacing a spent DPF with a brand new one can come as a costly surprise to the owner of the vehicle, or its manufacturer. But there's a solution.

Patented technique for remanufacturing the filters

Autocirc Rematrontech has developed a patented technique for remanufacturing the Diesel Particulate Filters (DPF), restoring them to a minimum of 95% of their initial capacity. Even modest quantities can enhance profitability while reducing environmental footprint.

The production of a Diesel Particulate Filter generates a substantial environmental impact, emitting 25.6 kg of carbon emissions. Remanufacturing the identical filter significantly reduces this footprint to a mere 3.3 kg of carbon emissions.

We have developed two patented processes for remanufacturing DPFs:

Passenger cars and Trucks & Working machinery

REMANUFACTURING OF

Heavy vehicle DPFs

The remanufacturing process for heavy vehicle filters is handled by a separate production department at Autocirc Rematrontech, adapted to handle DPFs of larger dimensions.

For this type of DPF, the goal is to achieve at least 95% of the original performance of the filter. New DPFs are used as reference objects in all tests.

The object is labelled with an ID number/QR code for full traceability. This can also be offered as a cloud service that provides full insight into the entire remanufacturing process in real time